To achieve this, specifications, quality requirements, and testing techniques need to be understood well to select the suitable SS Pipe (Stainless Steel Pipe) Specification pipe in any given project. TUSPIPE, a brand name in the steel piping solutions, provides a detailed guide to industries, builders, and engineers to base their decisions correctly. Due to decades of manufacturing experience, each SS of TUSPIPE pipe is safe and durable.

Understanding SS Pipe and Its Variants

A stainless steel pipe, also known as an SS pipe, is a hollow, round product formed out of an alloy that consists of iron and has a minimum of 10.5 % chromium content. This chromium will form a passive oxide film, giving a great resistance to corrosion, making stainless steel pipes available to a large scope of uses. TUSPIPE produces SS pipes that come in straight varieties such as round, square, and rectangular to fit various structural and practical requirements.

Key Specifications for SS Pipes

Accurate specifications are important when an SS pipe is to be chosen. TUSPIPE adheres to acceptable international standards such as the ASTM A312/A358 as generally applicable and ASTM A269 in regard to sanitary applications. These standards determine fundamental parameters including diameter, wall thickness, length, and end type. TUSPIPE can supply SS pipes with diameters between 1/8 inch and 24 inches and wall thickness grades between SCH 5S and SCH 80S. They normally are between 6 and 12 metres in length, with the choice of either plain, threaded, or grooved ends depending upon the assembly approach desired.

Comprehensive Testing for Quality Assurance

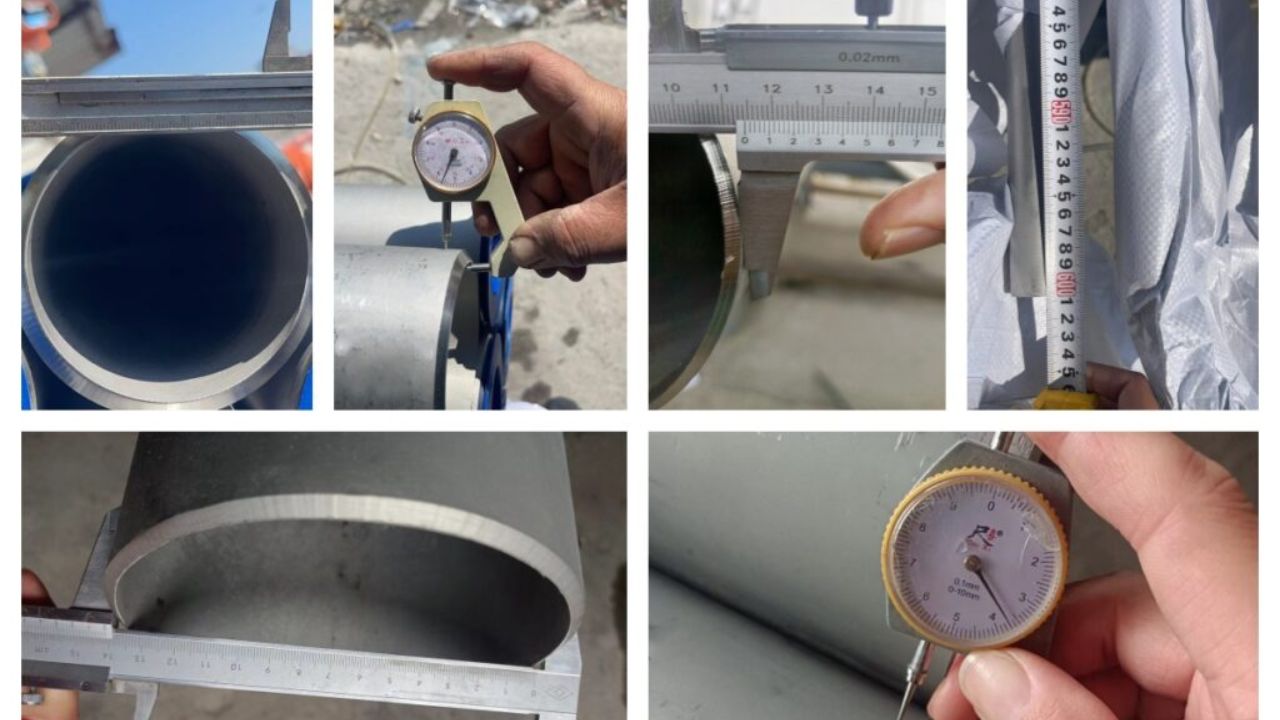

TUSPIPE places the toughest testing procedures in place to ensure that every SS pipe is performance-worthy. The initial inspection involves a visual inspection during which professionals analyze the surface, whether it is smooth, has an even color, or does not reveal visible defects such as cracks, wrinkles, or folds. This has the effect of ensuring that the pipe looks and finishes well to the standard of the customers and the industry itself.

Test instruments come next, and it is a familiar process of employing an instrument like a surface roughness tester and colorimeter to check finish and colour uniformity in a precise manner. In the case of welded SS pipes, weld integrity is determined by hydrostatic testing, and the purity of the weld interior or oxidation is also checked using this. These quality tests are important to secure long-term reliability in harsh environments.

Appearance and Marking Standards

On the basis of internal quality, TUSPIPE attaches a lot of importance to surface finish and marking. Weldings cannot contain slag, pores, or wavy appearances. There should be even brightness on the surface of the pipe with no scratches or color stains observed. The manufacturers accurately label each of the pipes with their name, specifications, lot number, and other data and codes to ensure complete traceability through production and installation.

Applications Across Industries

The stainless steel pipes manufactured by TUSPIPE are used in a very large number of industries. In the construction industry, the 304 stainless steel pipes have immense application as architectural supports and handrail systems, which allow functional structural properties in construction with an aesthetic superiority. Sanitary-grade SS pipes are also used in dairy processing and edible oil conveying systems, where the high Hygiene standards required in the beverage and food industries are taken care of. Chemical processing facilities use grades such as 317L stainless steel, which have been reinforced with molybdenum, making them more resistant to acid corrosion. Stainless steel pipes are even becoming increasingly popular in domestic water systems for their durability and ease of maintenance, as opposed to copper pipes.

TUSPIPE’s Commitment to Excellence

However, TUSPIPE has made a name for itself as one of the quality and innovation leaders with more than 25 years of experience in the process of manufacturing and installing pipelines. The manufacturing lines that are used by the company include a high-frequency welding machine of United States origin, and have thorough inspection equipment at each of the production steps. Each and every product has a distinct serial number to ensure full traceability, which assures accountability of the processes and customer confidence.

Conclusion

The type of stainless steel pipe selected determines not only how well a particular project is performing at that given time, but also in the future. Due to the acknowledgment of the distinctions between seamless and welded varieties, the attentive study of their specifications, and the rigid quality control of all the segments, buyers will be able to make educated decisions that suit their needs in their operations. The commitment of TUSPIPE towards international standards, rigorous inspection procedures, and expertise in particular industry guarantees that each of the SS pipes can live up to its word of strength, corrosion resistance, and endurance. Within the sphere of industries, as one of the providers of stainless steel pipes, TUSPIPE will be the optimal company to trust in terms of quality, precision, and customer satisfaction.